The right mold engineering expertise — fully integrated with your team.

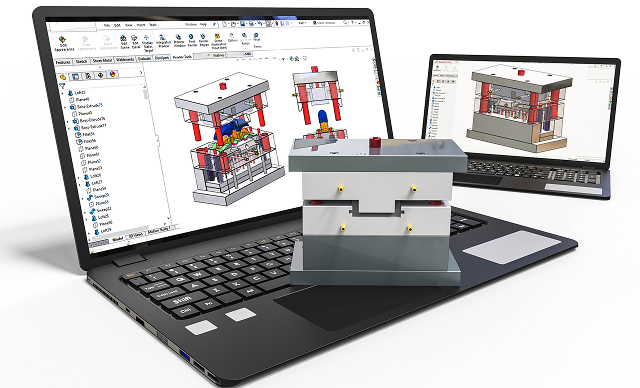

With JOT’s proven methodology, AI-powered recruitment, and the JOT APP, you can enhance mold design, streamline manufacturing, and optimize production — all with precision and efficiency.

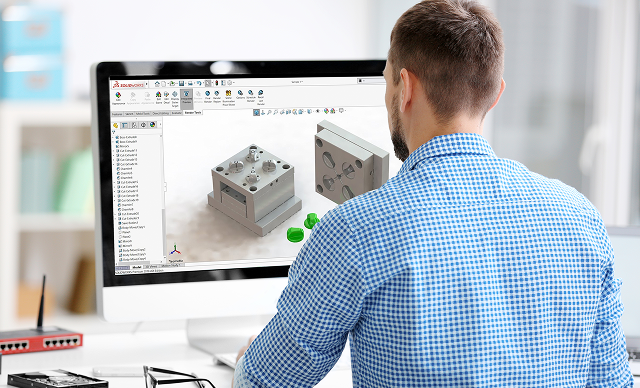

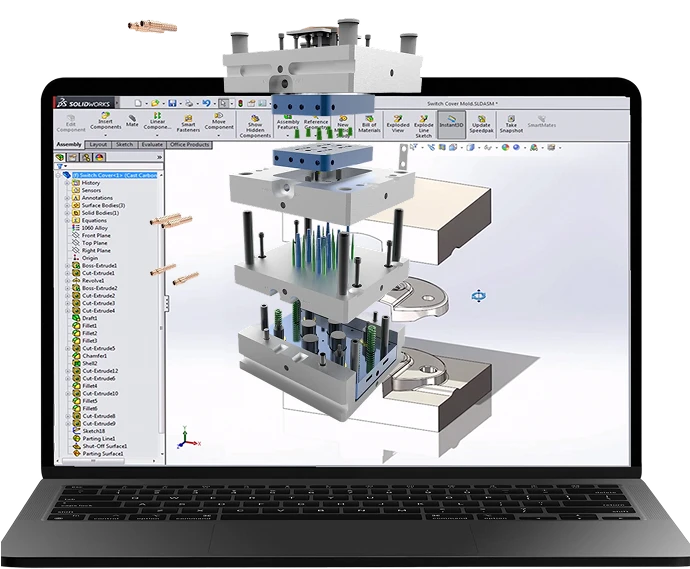

Modern manufacturing demands high-precision molds, faster cycle times, and flawless production processes.

At JOT, we connect you with expert mold engineers through a fully integrated outsourcing model — designed to support advanced manufacturing environments.

Full-time remote mold engineers working as an extension of your engineering and production teams.

At JOT, we go beyond standard outsourcing:

Discover how smarter outsourcing can help you drive faster, better, and more efficient product development.

In the manufacturing landscape, precision isn’t optional but it’s essential. Delays in tooling, design errors, or rework due to poor engineering decisions can derail your production, burn your budget, and waste valuable time.

That’s why companies across industries are turning to J.O.T Solutions. We embed top-tier mold engineers into your workflow, backed by intelligent matching, full-time dedication, and our real-time project management app.

You save weeks in hiring, cut engineering costs by up to 40%, and eliminate the typical headaches of managing freelance or in-house hires.

Let’s walk you through how it works and why it works better than anything else you’ve tried.

Hiring through the usual routes? Here’s what you’re likely to face:

J.O.T Solutions eliminates all of this.

We assign fully vetted, industry-specific mold engineers who work as a natural extension of your in-house team, minus the HR hassle, hiring lag, or long-term commitment.

Our engineers aren’t freelancers. They’re precision-driven professionals, backed by our systems, trained for real manufacturing outcomes, and ready to plug into your workflow from day one.

Step 1: Tell Us What You Need

Send us your part files, specs, and project scope. We analyze your needs in detail.

Step 2: AI Matching

Our algorithm pairs you with mold engineers who have hands-on experience with similar tools, materials, and industry specs.

Step 3: Interview & Approve

You meet the engineer, ask questions, and ensure they’re the right fit.

Step 4: Kickoff & Assign

We onboard your engineer, assign a project manager, and get started, typically within 48–72 hours.

Step 5: Track Progress via the J.O.T App

Get full visibility on timelines, revisions, communication, and delivery. You’ll always know what’s happening.

Need to scale? Shift direction mid-project? Replace an engineer? We make it seamless, no disruptions, no delays.

| Feature | Traditional Hiring | J.O.T Solutions |

| Time to Deploy | 4–8 Weeks | 2–3 Days |

| Cost | High Salary + Overhead | Pay-As-You-Go |

| Risk | High (Bad hires = $$$) | Zero Risk Trial |

| Tools & Oversight | Limited | J.O.T App + Project Manager |

| Flexibility | None | Total (Scale up/down anytime) |

Our engineers are experts in:

30–40% Cost Reduction

Compared to in-house and agency-based hiring

2–4x Faster Start Time

Engineers deployed in days, not weeks

Higher Output, Fewer Mistakes

Because great tooling = fewer rejects and faster cycles

Zero Headache

Now you don’t need HRs, no micromanaging, we handle everything

We get it, you don’t just need “someone.” You need the right mold engineer. One who understands your materials, your machines, and your goals. At J.O.T, we deliver exactly that, and we do it without wasting your time or money.

Whether you’re running lean or scaling fast — we make high-performance mold engineering effortless.

Yes. Our engineers are trained to bridge design intent and production execution. They coordinate with tooling vendors, designers, and operators.

We’ve built our system to be flexible. Need more hands? We add them. Need to switch gears? No delays. We handle everything.

Yes, the J.O.T App gives you full project visibility, real-time status updates, and direct team messaging, all in one place.

Find top talent effortlessly with our AI-powered form! Analyze work examples and connect with the right candidates fast.

Start building your team today!